Have you ever wondered what an elevator mechanic is doing while servicing your elevator? Here is an insider’s look at the steps that most elevator companies use in their inspections. These are general guidelines. The steps the elevator mechanic takes during an inspection can get much more involved.

Inside the Car:

- Otis Elevator Company, the world’s leading manufacturer of elevator and escalator systems, meets the most rigid demands of planning, building and design professionals. We offer you two easy-to-use planning and selection guides: Otis.the global leader in elevator and escalator systems 14 20 00/OTI BuyLine 1035.

- Analog phone line. – All oil lines and duct runs for remote machine room will be overhead. Electrical Contractor – If sprinklers are required, provide smoke sensing devices at elevator lobbies and/or at top of elevator shaft with electrical conductors terminating at elevator controller in machine room for automatic elevator recall system.

Hydraulic systems. The HydroFit elevator is a self-contained system that uses Otis’ proven holeless hydraulic design. Key components were redesigned to be more compact and able to fit in a standard hydraulic hoistway, eliminating the need for a machine room. Remains the same as a conventional system:. Hoistway depth. Hoistway width.

• Examine the interior of the elevator car for damage to the walls, ceiling, and handrails.

• Examine the position indicator lights and replace any burned out lights.

• Operate the elevator going up and down and check the leveling accuracy, acceleration, and deceleration. Make any adjustments deemed necessary.

• Check to make sure that the door moves smoothly and does not slam or bounce.

• Make sure the door restrictor operates properly and make any necessary repairs.

Outside the Car:

• Check the hall stations and lights and replace any burned out lights.

• Inspect the door panel and clearances.

• Test the Phase 1 firefighters’ service.

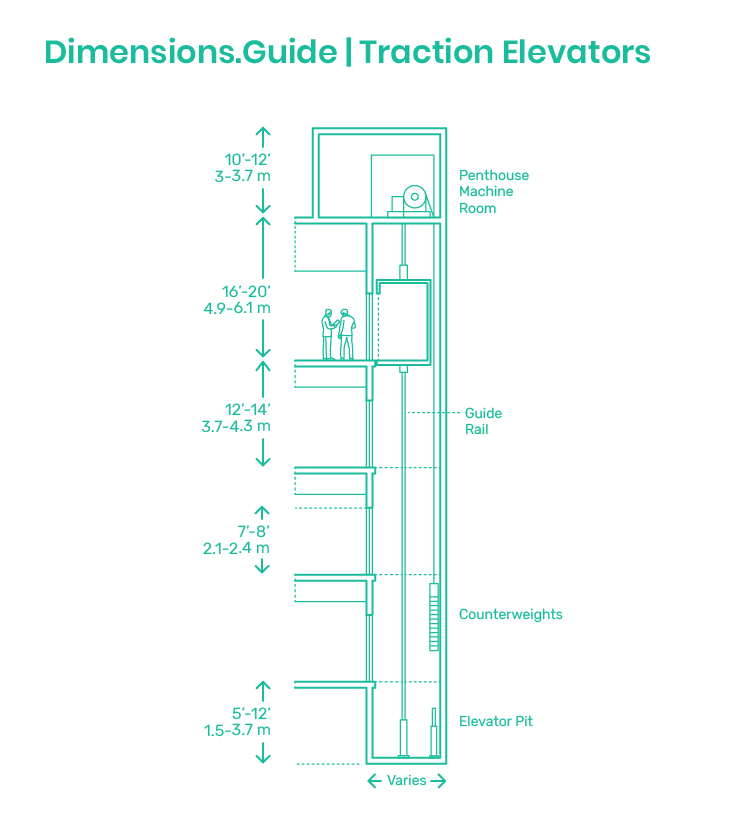

Machine Room:

• Make sure the machine room does not contain any material unrelated to the elevator.

• Check components for leaks, unusual vibration, or wear.

• Inspect electrical components for evidence of overheating or failure.

• Lubricate components, if necessary.

• Check the oil level.

• Make any necessary adjustments or schedule follow-up service.

Top of Car:

• Check that the stop switch and inspection station function properly.

• Remove any debris from the top of the car.

• Inspect any visible components, including rollers, guide rails, and leveling devices.

• Check the traveling cables for wear and inspect connections.

• Inspect the door operator and its components.

• Check the hoistway for evidence of rodents, fire safety, and vandalism.

Otis Elevator Emergency Phone Programming

Pit:

• Make sure that the stop switch, lights, and GFI outlet function properly.

• Clean the pit and check for signs of leaks.

• Inspect the spring buffers for signs of corrosion, alignment, and secure attachment.

• Inspect all visible components, including rollers, guide rails, safeties, and switches.

• Check the travel cable for wear, pinches, and snags.

• Make sure the sump pump is clean and operating correctly.

The elevator mechanic must fill out a log and note any observations, problems, and recommendations.